“In this video, all three of us are old and not one of us would recover from a fall. We’re old enough to know that we rely on our own judgment for our safety. Kept safe by our brains.”

Something Wonderful: Jobsite Safety and Taking Risks “All these things are profoundly unsafe. Sort of.”

Next post: The Damned Human Race by Mark Twain

Previous post: Origins of the State

Gerard Van der Leun

Gerard Van der Leun

Comments on this entry are closed.

I’ve mentioned a few times over the years here that in 2002 I slipped off the third step of a ladder and landed ass down on an L shaped piece of stamped sheet metal. An inexpensive shelf bracket. I wasn’t doing anything that would have appeared dangerous but the little slip turned into a freak accident. The metal sunk high into the back of my thigh. I didn’t know immediately that I had been impaled, got up and tried to walk off the pain and determine how bad I was hurt. I felt the back of my leg and realized there was something stuck in me. I pulled out the bracket and the blood flew. My roommate called 911. I took a ride in a meat wagon to the ER with a 200 lb. paramedic putting all his weight and pressure on my wound. Doctors were waiting outside when I showed up. Their fear was that I had cut an artery. Luckily I had not. I won’t bore all with the gore and story about me being naked in the ER (they cut all my clothes off in moments, except my t-shirt) although it is a good story over adult beverages. The point is, you can be careful all day long, wise in your estimations and still end up naked on a table surrounded by doctors, cops and hospital admin wanting to know your ability to pay. $.02 of advice, always be square with your Maker.

Great video. And the guy has it right. Your brain is the most important piece of safety equipment you have.

For instance, being on a ladder while using a cutting torch without a safety man is how I broke my hip in 1998. Cost me three months in a wheelchair, three months on crutches, three months on a cane and another three months limping around before I was released from light duty. Oh, and to this day, three three inch titanium screws in my hip socket plus the six inch scar from the surgery.

Being in construction for the past 40 years, honestly never had much use for a lot of the “safety” gear the law requires. Guard rails on scaffolds, yes. Harnesses and ropes tying me to the building, not so much…more hindrance than help.

Somebody that can empathize.

In 1975 I fell 800 feet in a parachute accident. Pelvis fractures in 7 places, one through the left acetabulum, broken left femur, severely dislocated left elbow requiring a cast for 6 weeks. 6 weeks in traction, 6 months in a wheelchair and a few months on crutches.

A ‘cruit fell through my canopy at 2000 ft in a night jump over Gelnhausen. We became entangled and spiraling. I cut loose, the ‘cruit didn’t and died, deployed the reserve but lacked the 200 feet needed for canopy inflation. To be honest, my cutting loose before he did possibly caused him further entanglement. That haunted me for decades. We both lost.

Due to “lost records” the army took more then 20 years to recognize my disability.

Mike & Ghost,

You guys win. Sheet metal impalement now sounds benign.

Regarding that pole barn construction, it is inherently more dangerous than say, standard stick built, because of the flimsy nature. I helped a friend build one last summer, 60’x80′, about 4 times the size of the one in the video.

I got hurt twice on construction projects, both times from stupidity, once my own, neither very seriously, although that wasn’t necessarily from lack of trying……I think of the dumb stuff we used to do in heavy construction before OSHA beat us into submission, and just shake my head.

There was this one guy who I was convinced was a fatality waiting to happen, either his or someone else. You see, safety rules are simple, you either follow them or someone gets hurt. But there’s a catch: the guy who breaks the rules doesn’t always pay the price. I had a serious chat with this guy’s boss, the general field superintendent about his lack of safety, and told him sooner or later somebody wasn’t gonna go home for supper because of this guy, and provided examples, after which I was reliably informed that he wasn’t as bad as I made out. But he would no longer be assigned to any of my projects because I more or less had it in for him. And that was true; I did not trust him to work safely. And I was right. Couple years down the road and I was working someplace else when I got the call, this guy was night foreman on a shut-down project, and half-assed a scaffold build. He rode it down when it failed. His crew survived because against all odds, they were all tied off with good safety equipment. They had to dangle for a few hours until the day crew showed up, because the foreman did not use a ground guy, yet another safety violation in a long, long string of far too many, but at least they lived.

And here is the thing, this nags at me from time to time. I was long gone when it happened. but still consider it partially my fault. If I had pushed it harder, maybe the guy would still be alive. Maybe getting fired for safety violations would have got his attention. I could have walked down the hallway and into the office of the president of the corporation and pushed it harder, but I’d already bucked the general field supt way farther than my pay grade allowed, given the corporate culture and my place in it, and his known vindictiveness when crossed, so……I went along to get along. This self-loathing may not be logical, but one thing’s for sure, I’ve not made that mistake since. I would hope this would helps someone else not make the same mistake ever.

Momma let me take a couple or more falls when I was growing up. I learned it hurts, be careful

This is a fabulous video. Completely true. Personally responsibility is everything. Growing up and even now, I often had/have scuffed knees or elbows cause I’ve learned to fall gracefully…. and mostly bounce.

Only our brains can keep us safer. Adult, mature brains are a treasure to behold.

May I approach the throne one more time?

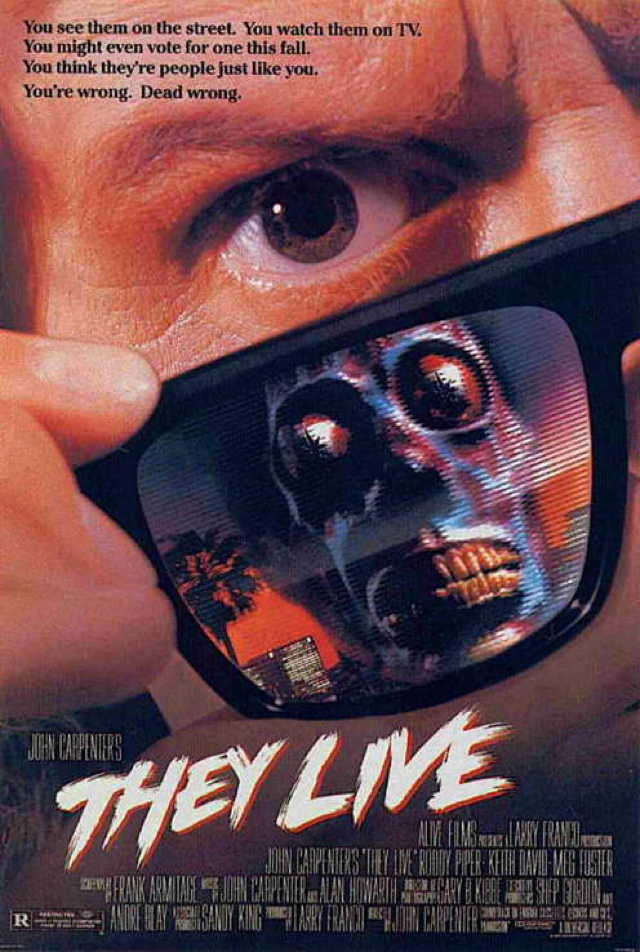

Zero Hedge features a piece on suicide and the hopelessness of people because the government controls more and more of our lives….sadly many believe that. In truth, it’s only those who believe that who succumb to its death sentence. In truth, personal responsibility/ direction never wait for government dictates to act or rescue them.

Painfully interesting stories y’all have shared. Glad you’re still with us.

Worked in a small metal fabrication shop for 10 yrs,which have some similar hazards to construction. Thankfully, no deaths occurred during my stay, but there were some bloody close calls, mostly due to stupidity/inattention. One guy just refused to wear safety glasses when using an angle grinder, said they were “too hot”. He made 3 trips that I know of to ER to get bits of metal dug out of his eyeballs. Dumb.

I don’t know how I survived heavy construction. Yes, I do. We just didn’t take risks. Thinking back, the risks we took were inherent and enormous, part of the trade 40′ aloft in 30mph gales in freezing January, but they weren’t a single one of them haphazard, unknown, foolish, unusual, or avoidable. Of course, I had youth on my side.

Being in construction for the past 40 years, honestly never had much use for a lot of the “safety” gear the law requires.

The law is an absolute ass, no more so then when it’s nannying your work. Without my responsibility I’m dead. With theirs I’m already in trouble.

When I bought my DeWalt tablesaw 20 years ago the first thing I did was take the blade guard off.

It’s the most scary tool I own. When it clicks on my blood runs and hides. The mutts leave. My wife has the habit of asking me things when I’m in the workshop. I told her that if I am working the table saw she is to never distract me. Ever.

While the blade guard is clear plastic, after studying how it works, I didn’t like how it blocked the view of the exact blade. It has a couple of pivot points in the get-up that looked like they could bind. And it has kick-back pawls and a splitter that will scratch the wood and potentially get hung up. In my opinion the saw is more dangerous with the safety items than without. My safety methods are far superior than any plastic guard can ever be. I still have all 10. But that almost was not true 30 years ago when, after cutting a piece of wood and moving my hand to turn the saw off my left thumb tip grazed across the top of the spinning blade. BAM! Instantly my thumb looked like a stalk of cauliflower. Then 1 second later, covered in tomato soup. Did I mention the pain? It went through the moon. Really bad, but not really. It could have been much worse. Ever notice how, when you cut the working parts of your hand, the palm, the finger pads, the pain seems much worse. I think the tissue in those areas has a different make up, and more nerves for feeling. WRap a shop rag around it and go sit down for a spell. Take the rag off, inspect, wrap with some handy tape hanging on the wall, and get back to it. Now, 3 decades later, I can’t find the scar. shrug

Took the guard off my Porter-Cable angle grinder too, it gets in the way, and prevents me from using it fully. I use it on my lathe. With a piece of wood installed on the lathe I crank it up to about 3000rpm then I fire up the guardless angle which has a 40 grit flap disk on it, then set about changing the way that piece of stock is shaped. If the wood has bark I will used the ballistic face guard and a ventilator. I learned that one the hard way. Bark is unpredictable. Sometimes it will shear off in large sheets. Most of the time it explodes in thousands of shards, landing as far as 20 feet away. When I get the shape about how I like it I change to a finer disk, say 120 grit, and do it again. Then 200, etc. Then I reverse the lathe and use the finest disk again to burnish the fine fibers.

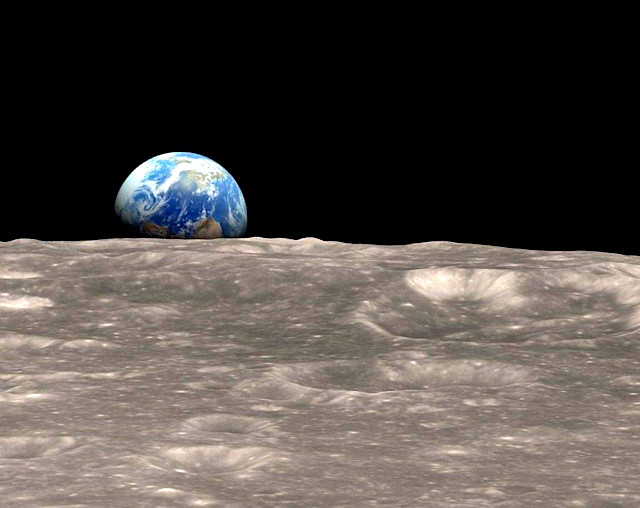

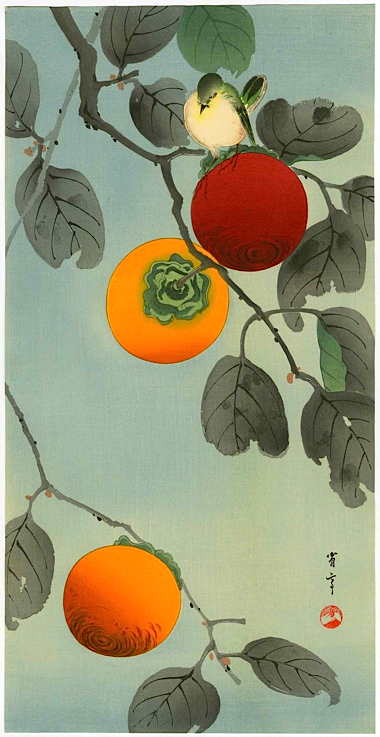

I continue the finish sanding process by using gritted paper up to 1200, then I switch over to micromesh which goes up to 10,000 grit. When thats done it is as smooth as glass. Then the good stuff starts. My legendary “Celestial” finishes were developed by me, trial and error, many, many times. Lots of failures. I use standard materials for the most part and I experiment all the time. After an initial coat of gloss poly that has dried for 2 days, I mount the wood (a bowl in this case) on the lathe and with a 3″ brush a put a thick daub of something cool right in the middle of the inside of the bowl. Then immediately, before the material can run, I crank the lathe of to 5000 rpms. POOF! Instantly the medium vaporizes and faster than any typhoon could ever be, that mushroom cloud is satan whipped around the inside of that bowl. We’re talking molecular at this point. I let the lathe run for at least 5 minutes at this speed to make sure the medium has set and mostly cured. Then I take it off and let it set for a few days. Next is some more sanding, of that medium, to get it as thin as possible. It is usually a bold color contrasting to the color of the wood. Say, bold royal blue metallic enamel, on clear white maple wood. Now I do it all over again using a different color, say, medium green acrylic mixed with yellow powdered wood stain. Poof, cloud, sand. Over and over. When I’m happy with the color and have everything as smooth as a baby’s hiney, I turn to the finish and protection. Satin poly is the rule here at Wood Magic Creations. I’ve tried everything else, expensive and cheap, and poly is the only thing that gives me the consistent results I require. I apply the poly with a 3″ Purdy brush while the wood is still on the lathe but turned off, I rotate it with the hand wheel. It dries for 2 days, then a run through all 12 sheets of micromesh, then a final cleaning with a tack cloth and clean water. Then 2 more days of drying. Over and over and over, sometimes 30 coats, to get the depth of finish I like.

When completely finished and ready to go to market and I stare down into the belly of the bowl it is like looking through the Hubble, at a place in the universe never before seen. Swirling, exploding center, pinprick dots randomly strewn by the millions across the ether. I name the bowls I create sometimes. The last one was laminated walnut, maple, and mahogany, 12″ in diameter and about 6″ deep. I named it “Tahitian Sunrise” and it is installed in an art gallery in Nashville, IN. like several others. This process can take up to about 2 months to complete, so I have maybe about 20 going on at the same time, in different stages. Like airbrushing, it’s a process rather than an event and most people never see the amount of time and effort invested. They only see the amazing end results and wonder how it was done. Trial and error. I’ve had many mistakes, some catastrophic, some expensive. Most, not. It’s all about the trying. Coming up with ideas and wondering if they will work, and if they don’t, why, and how to make them work. Thinking. Imagining. Working the hand to eye to brain trifecta and finding harmony.

@ghostsniper – March 7th, 2019 11:43am – enjoyed your entry, and thanks for the description. I’m not a lathe guy, but I can certainly understand it.